X-Ray Lead Glass: An Essential Component In Radiation Shielding

Radiation is a prevalent concern in various industries, particularly in healthcare and nuclear facilities. The protection of workers and the public from harmful radiation exposure is of utmost importance. One crucial component in radiation shielding is X-ray lead glass. In this article, we will delve into the properties, applications, and benefits of X-ray lead glass, highlighting its significance in providing effective radiation protection.

Table of Contents

- Introduction: Understanding X-Ray Lead Glass

- The Properties of X-Ray Lead Glass

- Applications of X-Ray Lead Glass

- Benefits of X-Ray Lead Glass

- How X-Ray Lead Glass is Manufactured

- Maintaining and Cleaning X-Ray Lead Glass

- Comparing X-Ray Lead Glass with Alternative Materials

- The Importance of X-Ray Lead Glass in Radiation Shielding

- Frequently Asked Questions (FAQs)

- Conclusion

1. Introduction: Understanding X-Ray Lead Glass

X-ray lead glass, also known as leaded glass or radiation shielding glass, is a specialized type of glass that contains a high concentration of lead oxide. It is designed to provide protection against the harmful effects of X-ray and gamma radiation. The unique properties of X-ray lead glass make it an essential component in various applications where radiation shielding is required.

2. The Properties of X-Ray Lead Glass

X-ray lead glass possesses several properties that make it suitable for radiation shielding. These properties include:

2.1. High Lead Content

X-ray lead glass typically contains a lead oxide content ranging from 55% to 70%. The high lead concentration enables effective absorption and attenuation of X-rays and gamma radiation.

2.2. Transparency

Despite its high lead content, X-ray lead glass remains transparent, allowing for clear visibility. This transparency is crucial in applications such as X-ray rooms and laboratories, where visual observation is necessary.

2.3. Light Transmission

X-ray lead glass is designed to allow a specific range of light wavelengths to pass through, ensuring optimal visibility while still providing excellent radiation protection.

2.4. Density

Due to its high lead content, X-ray lead glass is denser than regular glass. The increased density enhances its radiation shielding capabilities by reducing the transmission of radiation.

2.5. Durability

X-ray lead glass is manufactured to be robust and resistant to cracking or shattering, ensuring long-term reliability and safety.

2.6. Customizable Sizes and Thicknesses

X-ray lead glass is available in various sizes and thicknesses to accommodate different applications. This flexibility allows for tailored solutions that meet specific radiation shielding requirements.

3. Applications of X-Ray Lead Glass

X-ray lead glass finds extensive use in several industries and applications. Some notable applications include:

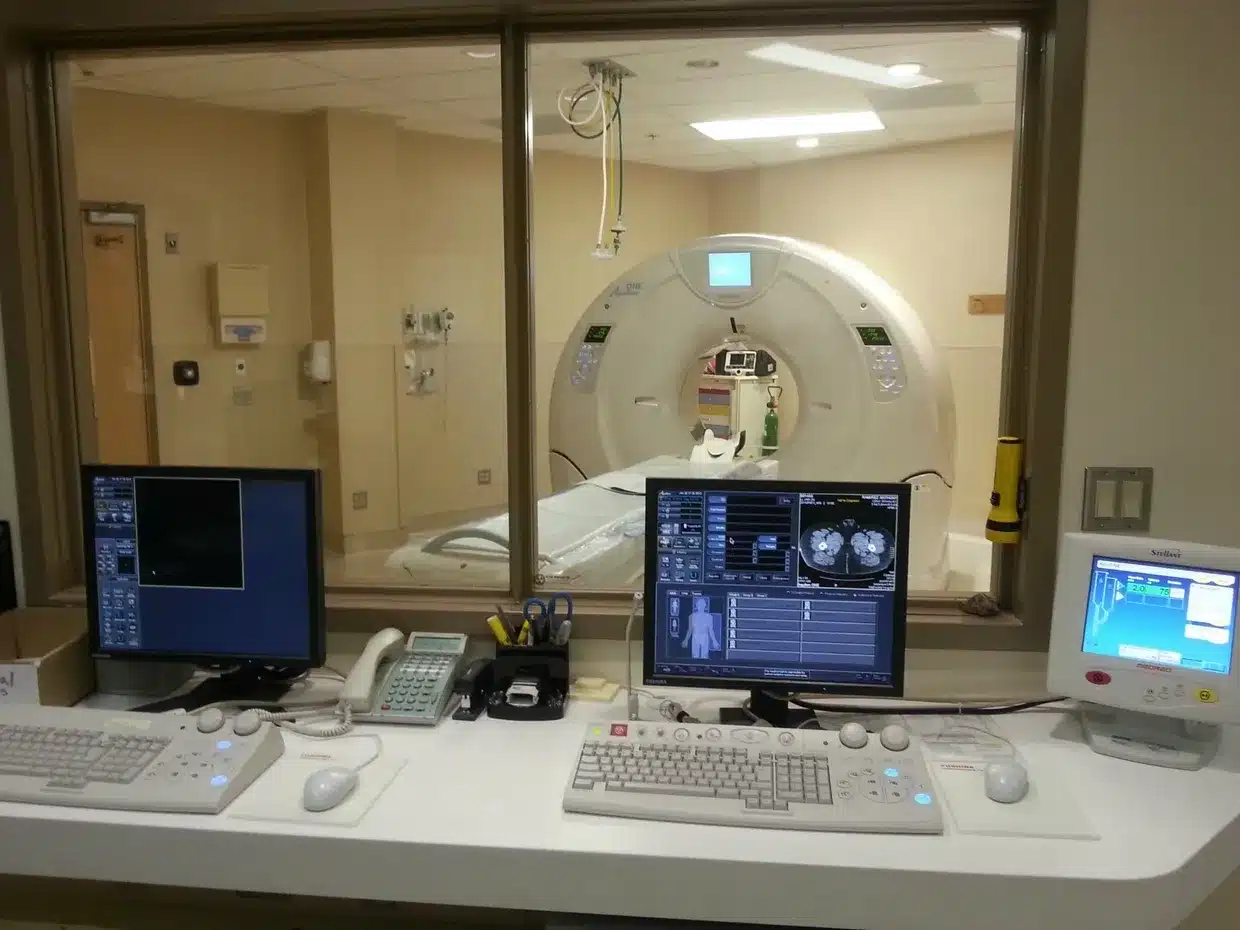

3.1. Medical Imaging Facilities

X-ray lead glass is utilized in X-ray rooms, CT scan rooms, and radiation therapy facilities to provide protection for medical personnel and patients. It acts as a barrier, preventing harmful radiation from escaping while enabling clear observation of the procedure.

3.2. Nuclear Power Plants

In nuclear power plants, X-ray lead glass is employed in control rooms and viewing windows. It ensures the safety of operators by minimizing their exposure to radiation while allowing them to monitor critical processes.

3.3. Research Laboratories

Research laboratories handling radioactive materials or conducting experiments involving radiation use X-ray lead glass in their facilities. It safeguards researchers and workers from potential radiation hazards.

3.4. Security and Inspection Systems

X-ray lead glass is integrated into security and inspection systems, such as baggage scanners and cargo screening devices. It provides protection for operators and effectively contains the radiation emitted by these systems.

4. Benefits of X-Ray Lead Glass

X-ray lead glass offers several benefits that contribute to its widespread use in radiation shielding:

4.1. Excellent Radiation Absorption

With its high lead content, X-ray lead glass is exceptionally effective at absorbing and attenuating X-rays and gamma radiation, minimizing the risk of exposure.

4.2. Enhanced Safety

By effectively containing radiation, X-ray lead glass enhances the safety of individuals working in environments where radiation is present. It provides peace of mind and reassurance to both workers and the public.

4.3. Optimal Visibility

X-ray lead glass maintains transparency, allowing for clear observation without compromising radiation protection. This visibility is essential in medical and industrial settings where precise monitoring is crucial.

4.4. Versatile Applications

The flexibility in size and thickness options makes X-ray lead glass suitable for a wide range of applications, ensuring that specific radiation shielding requirements are met effectively.

5. How X-Ray Lead Glass is Manufactured

The manufacturing process of X-ray lead glass involves several key steps:

- Batch Preparation: Lead oxide, glass frit, and other necessary ingredients are mixed together to form a homogeneous batch.

- Melting and Refining: The batch is heated in a furnace at high temperatures, melting the materials and refining the glass to remove impurities.

- Shaping: The molten glass is shaped into the desired form, such as sheets or blocks, using techniques like rolling or casting.

- Annealing: The shaped glass is slowly cooled in a controlled manner to relieve any internal stresses, ensuring its durability and strength.

- Quality Control: The final X-ray lead glass products undergo rigorous quality control measures to verify their radiation shielding properties and overall integrity.

6. Maintaining and Cleaning X-Ray Lead Glass

Proper maintenance and cleaning of X-ray lead glass are essential to preserve its performance and prolong its lifespan. Here are some tips for maintaining X-ray lead glass:

- Regularly inspect the glass for any signs of damage, such as cracks or chips.

- Clean the glass using mild, non-abrasive cleaners specifically designed for glass surfaces.

- Avoid using harsh chemicals or abrasive materials that could potentially damage the glass or its protective coating.

- Follow the manufacturer’s guidelines for any additional maintenance or cleaning recommendations.

7. Comparing X-Ray Lead Glass with Alternative Materials

While X-ray lead glass is a widely used radiation shielding solution, there are alternative materials available. Let’s compare X-ray lead glass with two common alternatives:

- Lead Sheets: Lead sheets offer high radiation shielding capabilities but lack transparency. They are primarily used in applications where visibility is not a concern.

- Barium Sulfate Concrete: Barium sulfate concrete provides good radiation absorption and is often used in construction. However, it is less flexible and versatile compared to X-ray lead glass, limiting its applications.

The choice of material depends on specific requirements, considering factors such as transparency, flexibility, and radiation shielding effectiveness.

8. The Importance of X-Ray Lead Glass in Radiation Shielding

X-ray lead glass plays a vital role in radiation shielding, ensuring the safety of individuals working in environments exposed to X-rays and gamma radiation. Its unique properties, including high lead content, transparency, and customizable options, make it an indispensable component in various industries. By utilizing X-ray lead glass, organizations can create safe working environments while maintaining visibility and operational efficiency.

Frequently Asked Questions (FAQs)

No, X-ray lead glass does not pose any direct harm to human health. It is designed to absorb and attenuate radiation, protecting individuals from its harmful effects.

Yes, X-ray lead glass can be recycled. It is important to follow proper recycling procedures to ensure the safe handling and disposal of lead-containing materials.

X-ray lead glass requires regular inspection for damage and should be cleaned using mild, non-abrasive cleaners specifically designed for glass surfaces. Following the manufacturer’s maintenance guidelines is essential.

Yes, X-ray lead glass can be used in portable radiation shielding applications. Its customizable sizes and thicknesses allow for flexibility in designing portable shielding solutions.

The cost of X-ray lead glass may vary depending on the size, thickness, and quantity required. While it may have a higher initial cost compared to some alternatives, its effectiveness, durability, and transparency make it a valuable long-term investment.

Conclusion

X-ray lead glass is a critical component in radiation shielding, providing effective protection against X-rays and gamma radiation. Its unique properties, such as high lead content, transparency, and versatility, make it an ideal choice for various applications, including medical imaging facilities, nuclear power plants, research laboratories, and security systems. By utilizing X-ray lead glass, organizations prioritize the safety of workers and the public while ensuring optimal visibility and operational efficiency.

In conclusion, X-ray lead glass is an indispensable solution in radiation shielding, safeguarding individuals and enabling crucial operations in industries where radiation exposure is a concern.

Explore More News

Fire Rated Glass for Aircraft Interiors: Challenges and Solutions

Embark on a journey to elevate aviation safety to new heights with Liberty Shielding’s pioneering innovation – fire rated glass…

Fire Resistant Glass: Key Features and Applications in Manufacturing

Step into the realm where security harmonizes with innovation. Unveil the extraordinary attributes of our fire-resistant glass, meticulously crafted to…

Bullet-Proof Windows: Balancing Safety and Aesthetics

Step into the future of unparalleled security with Bullet-Proof Windows from Liberty Shielding. As the industry leader, we redefine safety…