Level 1 Bullet Resistant Glass Data Sheet (pdf)

Level 2 Bullet Resistant Glass Data Sheet (pdf)

Level 3 Bullet Resistant Glass Data Sheet (pdf)

Level 4 Bullet Resistant Glass Data Sheet (pdf)

Level 5 Bullet Resistant Glass Data Sheet (pdf)

Level 7 Bullet Resistant Glass Data Sheet (pdf)

Level 8 Bullet Resistant Glass Data Sheet (pdf)

Bullet-resistant glass can save your life and it is incorporated into many different everyday buildings specifically for that purpose. While bulletproof glass is different from regular glass, unless you know what to look for, it is unlikely that most people will notice; which is exactly the point. Not every bullet-resistant glass is created equal.

Bullet-resistant glazing is made by laminating several layers of glass with polycarbonate. Essentially, the more layers that are included decide the glass’s bullet resistant level.

In addition to these layers, an extra safety precaution is making the glass with no-spall. When the glass has spall, it means that when a bullet hits it, the glass is ejected out the other side, even though the bullet is stopped. Those glass shards travel at nearly the same velocity as a bullet and therefore, that flying glass can still hurt or kill people. Obviously, this is still dangerous.

Fortunately, all of Liberty Shielding’s bulletproof glass has no spall, meaning no glass can injure people on the other side when shot. Instead, the bullet is lodged in the glass, and any glass that does escape falls out of the side the bullet entered. This keeps everyone on the “asset side” of the glass safe. In addition to the high-quality, the safety and peace of mind it brings makes it well worth the investment.

Bullet-resistant glass is designed to look like normal glass. It is clean, clear, and perfectly transparent. The only thing a person might notice about it, without shooting it, is that it is thicker than most glass panes. This is because of the multiple layers and lamination process.

Although, when the bullet-resistant glass is shot, the difference is immediate. The bullet gets stuck inside the glass, which is convenient for ballistic testing. Instead of exploding, the glass breaks up into little crystals but doesn’t break even after multiple shots. Once the glass is hit by a bullet, it is no longer transparent which provides an additional layer of protection, since you cannot shoot a target you can’t see.

Bulletproof glass is used in many different buildings and vehicles throughout the United States. There are plenty of reasons to have bullet-resistant glazing on the windows and glass enclosures throughout your office. All of those reasons are based on the protection of the people inside.

In some buildings, bulletproof glass is optional but for many, it has become standard procedure:

However, these are not the only places that can benefit from bullet-resistant glazing on their glass. Despite its durability, bullet-resistant glazing panels can be designed to fit your specific architectural needs. There are certain places where bullet-resistant glazing is not primarily for protection against bullets. Schools and public buildings within Tornado Alley are also reinforced with bulletproof glass to protect the building and the people inside from the usually unpredictable natural disaster.

The first generation of safety glass was found by accident. Edouard Benedictus’ clumsiness in 1903 started the true evolution of bulletproof glass. Benedictus was a French chemist, who accidentally dropped a flask on the ground while working in his lab. The flask he dropped had a liquid nitrate solution. This solution covered the glass with a protective plastic layer. Thus, the flask broke but did not shatter. That gave Benedictus an idea and in 1909 he filed the first-ever patent for laminated safety glass. Since that time, bullet-resistant glass has improved significantly and become more dynamic.

The military used it in WWII to manufacture an early version of safety glass for American bombers. However, it was the banks and museums who used it first commercially. Police stations didn’t start using bulletproof glass until much later. Since then, many police departments throughout the United States have upgraded their facilities to meet higher ballistic resistance standards.

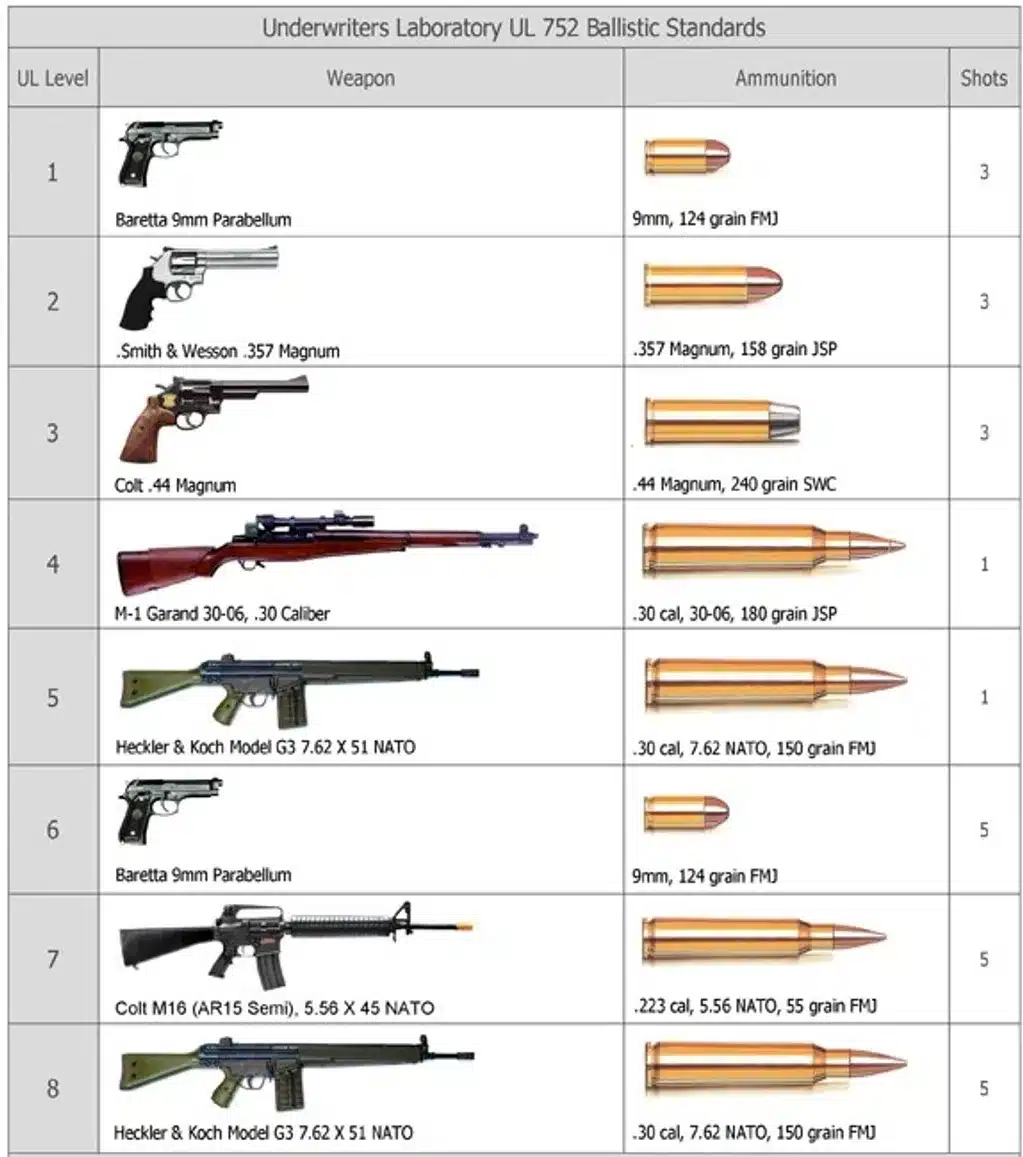

There are different levels of bullet-resistant glazing on the market today. The bullet resistant level selection is a result of the potential threat and the capabilities of the architecture. After all, weight is a factor and needs to be considered to maintain the long-term integrity of the building structure.

Ultimately, though, each building has a choice of the level they are going to want to install. After all, any protection is better than nothing.

Here are the different levels that we offer.

Levels 1-3 are optimized for clarity and are easy to customize. This level is primarily used for indoor use, such as bank tellers, museums, public buildings, and schools. These types of buildings have a higher threat level because there are more people in and out of the building on any given day.

Levels 4-8 are used on a case-by-case basis. Typically, projects do not call-out a level higher than three. These higher levels are built to withstand rifles and automatic weapons; they are not used by your average every-day robber.

Additionally, the price for the Levels of 4-8 is outside the scope for many budgets. Unless you know that you need this from the start, you likely will not have the budget (or the need) to implement these levels into your building plans.

In addition to all Liberty Shielding’s bullet-resistant glazing being no spall, there are also a few other specifics that make our bulletproof glass better.

In addition to having many bullet resistant levels, thicknesses and sizes available, we also offer other options to make your glass fit your specs and requirements. Here are some additional options that are available upon request:

That way, Liberty Shielding takes care of the whole project from start to finish. Obviously, if you are looking into bullet-resistant glazing, you are looking to secure your building. Single-source responsibility will make your security become a reality.

In summation, the idea that bullet-resistant glazing is necessary might seem scary. After all, no one wants to think about the possibility of being shot at, bulletproof glass or not. However, the range of different buildings and uses for bulletproof glass makes it a precaution. After all, when the impossible happens, it is always better to be prepared.

For more information or to order your bullet-resistant glass contact Liberty Shielding today!

Optional Low Iron Bullet Resistant Glass

Level 3 Glass front side after .44 Magnum shooting test

Level 3 Glass back side after .44 Magnum shooting test; No penetration, no spall.

Level 3 Bullet Resistant Polycarbonate Round fully captured, no penetration

UL Level 8 Bullet Resistant Glass

Level 8 Glass Front side after 5 shots of 7.62×51mm NATO

Level 8 Glass Back side after 5 shots of 7.62×51mm NATO; No penetration, no spall.

UL 752 Levels

| Bullet Resistant Level | Product | Thickness | Location | Weight PSF | Light Transmission | Threat Resistance |

| Handgun UL 752 Level 1 NIJ 0108.01 Level IIIA | Laminated Glass Clad Poly | 0.68″ | Interior or Exterior | 8# | 81% | Handgun up to 9mm 3 shots |

| HandgunUL 752 Level 2 | Laminated Glass Clad Poly | 0.95″ | Interior or Exterior | 11# | 78% | Handgun up to .357 Magnum 3 shots |

| Handgun UL 752 Level 3 | Laminated Glass Clad Poly | 1.125″ | Interior or Exterior | 13# | 77% | Handgun up to .44 Magnum 3 shots |

| Rifle UL 752 Level 4 | Laminated Glass Clad Poly | 1.25″ | Interior or Exterior | 15# | 75% | Rifle .30-06 1 shot |

| Rifle UL 752 Level 5 | Laminated Glass Clad Poly | 1.37″ | Interior or Exterior | 16# | 74% | Rifle .308 (7.62×51) 1 shot |

| Rifle UL 752 Level 7 | Laminated Glass Clad Poly | 1.94″ | Interior or Exterior | 24# | 69% | Rifle 5.56mm (.223) 5 shots |

| Rifle UL 752 Level 8 | Laminated Glass Clad Poly | 2.4″ | Interior or Exterior | 27# | 57% | Rifle .308 (7.62×51) 5 shots |

| Handgun UL 752 Level 3 NIJ 0108.01 Level IIIA | Laminated Polycarbonate | 1.25″ | Interior Only | 8# | 72% | Handgun up to .44 Magnum |

| Handgun UL 752 Level 3 NIJ 0108.01 Level IIIA | Laminated Acrylic | 1.25″ | Interior Only | 8# | 85% | Handgun up to .44 Magnum |

| Handgun UL 752 Level 3 NIJ 0108.01 Level IIIA | Laminated Pyrostop | 2.44″ | Interior or Exterior | 26# | 74% | Handgun up to .44 Magnum 2 Hour Fire Rated |

All products listed above meet:

All products listed above are available with: