You can request a quote for your specific application by clicking the button on the right (recommended).

Or you can use the “Order Online” button to purchase directly from our ecommerce site.

Need help selecting the right lead backed drywall?

Our team is here to provide quick quotes and expert support.👉 Call now or request a quote online — stock ships in 2–3 days!

Lead backed drywall, also known as lead-lined sheetrock, is gypsum board laminated with pure sheet lead on the back side. It’s commonly used in medical imaging rooms, labs, and facilities where protection from X-rays and gamma rays is required.

Yes. The lead remains in solid form and is laminated to drywall, so there’s no risk of it becoming airborne. It provides safe, effective shielding from radiation.

It’s commonly installed in General X-ray rooms, C-arm radiography rooms, PET/CT scan rooms, and labs that handle radioactive materials

Lead’s high molecular density blocks radioactive particles, preventing them from passing through walls or ceilings and protecting people in adjacent spaces.

Permanent and effective radiation shielding

Can be used for both walls and ceilings

Excellent sound barrier

Reduces the risk of radiation leakage when installed properly

Standard panels are 4’x7′ with lead on 8′ boards, but custom sizes up to 12′ are available. Options include ½” non-rated or ⅝” fire-rated drywall and even plywood for heavier lead backing.

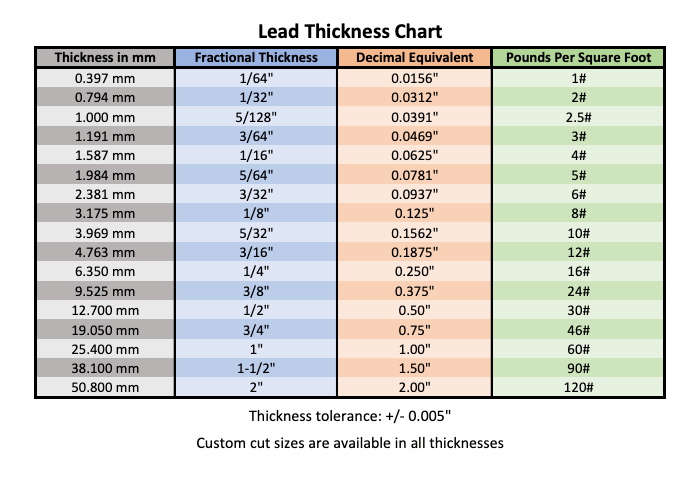

We offer 17 lead thicknesses, ranging from 1/64″ (1#) up to ¼” (16#). Heavier options are available with plywood backing—up to 2″ thick (120#).

Yes. Each sheet comes with:

Optional corner protectors for full coverage

One 2″ vertical batten strip

50 lead discs to cover screw heads

Absolutely. We offer custom lead-lined drywall and plywood with fire-rated, mold-resistant, and abuse-resistant options tailored to your project needs.

Shielding plans must be developed by licensed experts such as radiation physicists or medical health physicists. The design must comply with federal law and industry standards to prevent radiation leakage.

A shielding report from a certified expert (e.g., American Board of Radiology, Health Physics) is required to ensure your facility meets safety regulations.

The lead must be a solid, unpierced sheet. Joints should run vertically and be covered with lead batten strips. All wall penetrations (e.g., outlets, pipes) must also be properly shielded to pass inspection.

Screw spacing: 8″ on edges, 12″ on studs

Use construction adhesive for lead batten strips

Cover all screw heads with lead discs

Shield around all wall fixtures and penetrations

Most custom drywall and plywood orders ship within 2–3 business days.

Yes, our team offers guidance and support throughout the process to ensure your facility meets safety and compliance standards.

Since this material is very common for medical safety, our lead lined drywall meets ASTM C 1396 requirements and the pure sheet lead that we use to line our sheetrock meets Federal Specification QQ-L-201 F, Grade C, and ASTM B749-03, type L51121, which is factory laminated under high pressure to the backside of the drywall.

We provide high-quality drywall with a lead lining that has been laminated onto the sheetrock. Although lead is a heavy metal, it is safe to use as prevention of radiation, x-rays and gamma rays; since it remains in solid lead form the entire time there is no risk of the lead becoming airborne.

Lead backed drywall (also called lead backed sheetrock) is gypsum wall board with lead laminated to the backside that faces the studs. It is required in almost every radiation imaging room since the lead lining provides protection from x-rays and gamma-rays.

The most common rooms for lead backed drywall to be installed are C-Arm Radiography, General X-Ray rooms, P.E.T and CT Scan rooms, and labs with radioactive materials or equipment.

There can be huge ramifications from radiation exposure to your body. It can also cause birth defects in unborn children, and serious health defects if the x-ray technician is not properly protected. Lead backed drywall is the most effective method of protection against all of these radioactive ramifications for improper safety precautions.

Lead stops radioactive particles from passing through the wall since lead has an incredibly high molecular density.

Adhering sheets of pure lead to the back of the sheetrock/drywall ensures that the lead surrounds the room and prevents leaks of any kind.

Radiation Shielding

Building the walls out of lead backed drywall can provide a permanent shield from radiation since it is involved in the structure of the room, not just a partition or a temporary shield. This all-around protection is incredibly important for employees or technicians in labs or rooms with constant exposure or frequent exposure to radiation and radioactive materials.

Essentially, lead backed drywall provides:

Our Custom Lead Backed Drywall Services and Products

We create custom products and work within our customer’s needs, so each order is unique to the clients requirements. The time to fill and produce orders is typically two to three days.

Our products include lead lining on ½ inch non-rated sheetrock or ⅝ inch fire-rated sheetrock gypsum wallboard. We also offer lead backed plywood with ½” or ¾” fire retardant plywood.

The standard size of the lead lined drywall is 4 foot by 7 foot lead on 8 foot board. We can also fabricate up to 12 foot board and full height lead if the project requirements call for that.

We include one 2-inch vertical batten strip per sheet for joints and 50 lead discs per sheet to be placed over the tops of the screw heads for maximum protection. Optional lead corner protectors are also available.

We offer 17 different lead thicknesses for the lead backing of the drywall. These thicknesses range from 1/64 of an inch (1#) to ¼ of an inch (16#). We also offer the fabrication of lead-lined plywood for heavier thicknesses of lead backing, ranging from ⅛ of an inch (8#) to 2 inches (120#).

We also offer additional options for your lead backed drywall, such as mold-resistant and abuse-resistant wallboards.

Your Radiation Shielding Report

Several rules and regulations must be followed when going about installing or applying lead backed drywall as radiation protection to your building.

The radiation shielding must be designed by an expert in the industry. These experts could be radiation physicists, county health officers, or medical health physicists who are well educated in radiation protection and capable to design radiation protection for radioactive medical imaging.

The person who designs the structure of the protection in the walls must be certified by the American Board of Radiology, American Board of Health Physics, or the Canadian College of Physics and Medicine.

It is required by federal law to have a shielding report produced by a licensed radiation physicist, because without this report you can have radiation leaking into the rest of your building and have dangerous repercussions physically and financially.

You must make sure that your expert is highly engaged in the early stages of the design process to ensure that your design fits all shielding requirements for your imaging equipment and your location.

The shielding regulations and requirements for each location will be different, and a radiation physicist will make sure that your radiation imaging room is contained without leaks.

The expert will be able to help identify the proper choice of radiation facilities and building construction to maximize the safety precautions of the spaces being protected.

Whoever you choose as your expert should understand the laws and have all the pertinent information about exposed radiation, proposed radiation equipment, and how it will be used in the building, the type of building, and the surrounding building occupancies or spaces.

Requirements for Lead Backed Drywall

The lead lining on the drywall is required by NCRP to be a whole, unpierced, monolithic sheet prior to installation. Otherwise, radiation leakage can occur.

If your requirements for the radiation application exceed ⅛ of an inch and are unable to support the thickness of the lead, you may want to use lead backed plywood to maintain a rigid structure.

The installation must be executed properly, there to be no leakage of radiation. The seams of the walls should be installed with the joints of the walls running vertically from ceiling to floor and every joint must have a lead batten strip overlapping the lead lining on the drywall. Lead backing at every penetration is required; including all electrical outlets, pipes, ventilation, etc. If you follow these standards correctly, you will pass inspection of your lead backed drywall room.

Industry Standard Tips for Installing Lead Backed Drywall

Ensure that when you fasten your lead backed drywall panels, your screw schedule should be 8 inches on the edges of all the drywall and 12 inches on the intermediate studs with standard drywall screws.

You should apply the 2 inch wide batten strips of the sheet lead of the same thickness as the lead backing on the drywall to the joint studs. This can be done using standard construction adhesive.

The lead sheet strips will assure that you meet standards for a 1/2-inch lead overlap on all seams.

Ensure that all the fasteners and screws are covered with the lead discs. ⅜-inch diameter discs are the recommended standard and an equal thickness as the lead backing on the drywall.

When installing the screws (standard drywall screws will be fine) make sure that the screws dimple into the drywall slightly. This, with the lead discs secured on top of the heads of the screws, will help eliminate any radiation leakage at any point of fastening or conjunction.

When installing lead backed drywall, you will also need to use lead backing on the areas around any switches, levers, or fasteners in the walls. These areas are a common reason for radiation leaking into the surrounding rooms.

To conclude, please ensure that you have the proper precautions and experts working on your team when trying to protect your building and physical safety.

This is a vital piece of protecting your building, and we offer support throughout the order process to ensure your patients and employees safety.